Micron said on Tuesday that it had started volume production of DRAM chips using its latest 1α (1-alpha) process technology. Initially the company will use the new node for LPDDR4X and 8Gb DDR4 memory ICs, but the company will eventually use the new fabrication tech to produce all of its DRAMs.

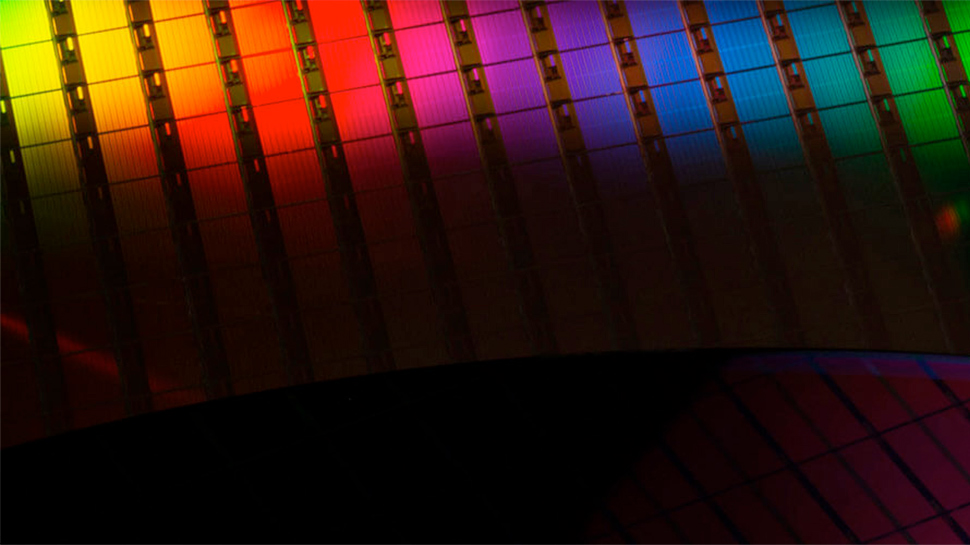

Unlike its rivals, Micron does not plan to use extreme ultraviolet (EUV) lithography for at least a few years. However, as the company still needs to increase the density of its memory chips and reduce its per-bit costs, it has to rely on other innovations to shrink its DRAMs. Micron’s 1α node offers a 40% improvement in bit density and a 15% drop in power consumption compared to 1Z. It also offers higher performance potential. Micron had to improve array efficiency design and use new materials, including better conductors, better insulators, and new machinery to deposit, modify or selectively remove those materials.

Micron’s 8Gb DDR4 chips, which are already shipping in volume, are the first to use its 1α process technology. The company will begin shipping LPDDR4X chips made with the 1α node later this month. Micron will eventually transition virtually all of its DRAM to 1α, including DDR5, HBM2E, and GDDR6/GDDR6X.

Micron currently uses its 1α technology in its A3 fab in Taichung, Taiwan. In the future, the company will adopt the new technology at other fabs.

Micron has also completed validation of its 1α-based DDR4 on the latest server platforms, including AMD’s Third-gen EPYC ‘Milan’ processor. The same chips can also be used for notebooks.