Legendary Intel CTO and CEO Pat Gelsinger is now serving as executive chairman at xLight, a startup that develops a free electron laser (FEL) technology as a light source for extreme ultraviolet (EUV) lithography systems. Using a particle accelerator to generate light for litho machines is something that has been discussed previously, but xLight claims that it can produce such a source by 2028, while maintaining compatibility with existing tools.

“As part of my new role at Playground Global, I have joined xLight as executive chairman of the board,” Gelsinger wrote in a LinkedIn post. “I will be working closely with Nicholas Kelez and team to build the world’s most powerful Free Electron Lasers (FEL) by leveraging particle accelerator technology.”

EUV lithography is an advanced technique used for semiconductor manufacturing to create extremely small — we are talking about an 8nm resolution for High-NA EUV and a ~13nm for Low-NA EUV — circuit patterns on silicon wafers that uses EUV light with a 13.5nm wavelength. At present, only ASML can build EUV litho systems and these use an intricate way of producing light with a 13.5nm wavelength. But there is more than one way to create a light with an extremely short wavelength to produce chips with an 8nm ~ 13.5nm resolution. One of them is to use a particle accelerator as a laser produced plasma (LPP) light source.

xLight has created an LPP source that delivers four times the power of the most advanced systems available today, according to the Gelsinger’s post. ASML’s Twinscan NXE:3600D has a 250W LPP source, whereas the NXE:3800E is equipped with a ~300W source. While ASML has demonstrated EUV source powers above 500W in research settings, these higher power levels are not yet available in commercially deployed systems. Yet, ASML continues to work towards increasing EUV source power, with plans to double output to 600W and a roadmap extending beyond 1,000W. Apparently, xLight Gelsinger claim that the company has an LPP source that is beyond 1,000W today and that will be ready for commercial applications by 2028.

Gelsinger claims that xLight’s technology cuts per-wafer costs by around 50% and lowers both capital and operating expenses by threefold, which is a major leap in manufacturing efficiency. While we do know the approximate price of ASML’s Twinscan NXE:3800E (around $240 – $250 million), we do cannot really guess the price of the light source alone. Meanwhile, the claim that the new LPP source can lower capital expenses and operating costs by three times can potentially mean a substantial decrease of a FEL-based litho tool cost compared to today’s machines from ASML.

Speaking of ASML, it is important to note that xLight does not aim to replace ASML’s EUV litho tools, but produce an LPP source that “will be connected to an ASML scanner and running wafers by 2028.” This may mean that xLight’s LPP source will be compatible with existing ASML tools, but it is unclear whether it will be compatible with next-generation High-NA EUV tools (most probably yes, as they use the same LPP sources as existing Low-NA EUV tools). It also remains to be seen whether xLight’s LPP source can be attached to TwinScan machines in fab environments.

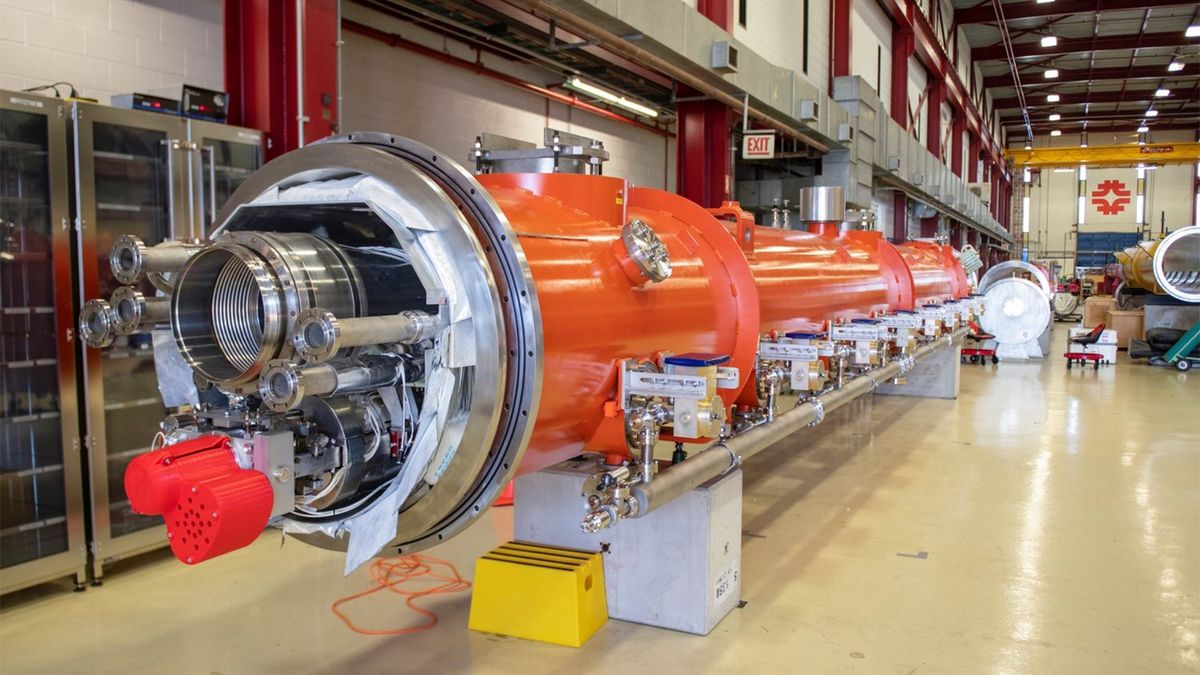

Remember that fabs are built to accommodate specific tools and in case of Low-NA EUV systems it means that the light source is located below the machine itself, whereas in case of High-NA EUV tool its LPP source is located on the same level, so any ‘third party’ LPP source has to take these facts into account. For now, the particle accelerator looks rather big for existing fabs, so FEL is probably applicable for next generation of fabs if it is proved efficient.

It is noteworthy that while xLight believes that its FEL technology represents a multi-billion-dollar opportunity in the long term, it also opens near-term revenue in other key areas. The company believes that its systems are well-suited for high-power metrology and inspection tools. Perhaps, even beyond semiconductors, as it can address challenges in national security and biotech: from point defense and space debris control to medical imaging and scientific research.